Clean Systems

Clean Systems- Reduction in equipment footprint by half over competition

- Lower cost of ownership by almost 50%

- Proven high reliability from system designs with as few as three moving parts

- Plasma Cleaning

- Photoresist removal/descum

- Polyimide, organics and CuO removal

- Surface activation

- Adhesion promotion

- Plasma surface decontamination

- Choose among 100+ chemical precursors

- Achieve up to 3X improvement in temperature uniformity over our competition

- Leverage YES expertise and proven history in deploying thousands of systems across various emerging industries

- Surface modification

(adhesion / hydrophobic / hydrophilic) - Adhesion improvement

- Anti-stiction layer

- Surface priming for microarrays

- DNA sequencing and microfluidics

- Self-assembled monolayer deposition

and removal - Seed layer for metallization

- Achieve up to 50% improvement in cure time

- Cut total cost of ownership (TCO) in half

- Improve the performance of products with less outgassing, greater film stability, and higher reliability

- Polyimide, BCB or PBO cure

- Wafer-to-wafer bonding anneal

- Vacuum anneal up to 400°C

- Pre-metal or pre-PVD bake and degas

- Repeatable, controllable results in high volume manufacturing

- Complete bonding with excellent reliability

- Excellent particle performance

- 3D packaging

- CMOS image sensors under panel

- Polyimide bake

- Copper anneal

- Wafer-to-wafer bonding annea

- DtP and PtP bonding

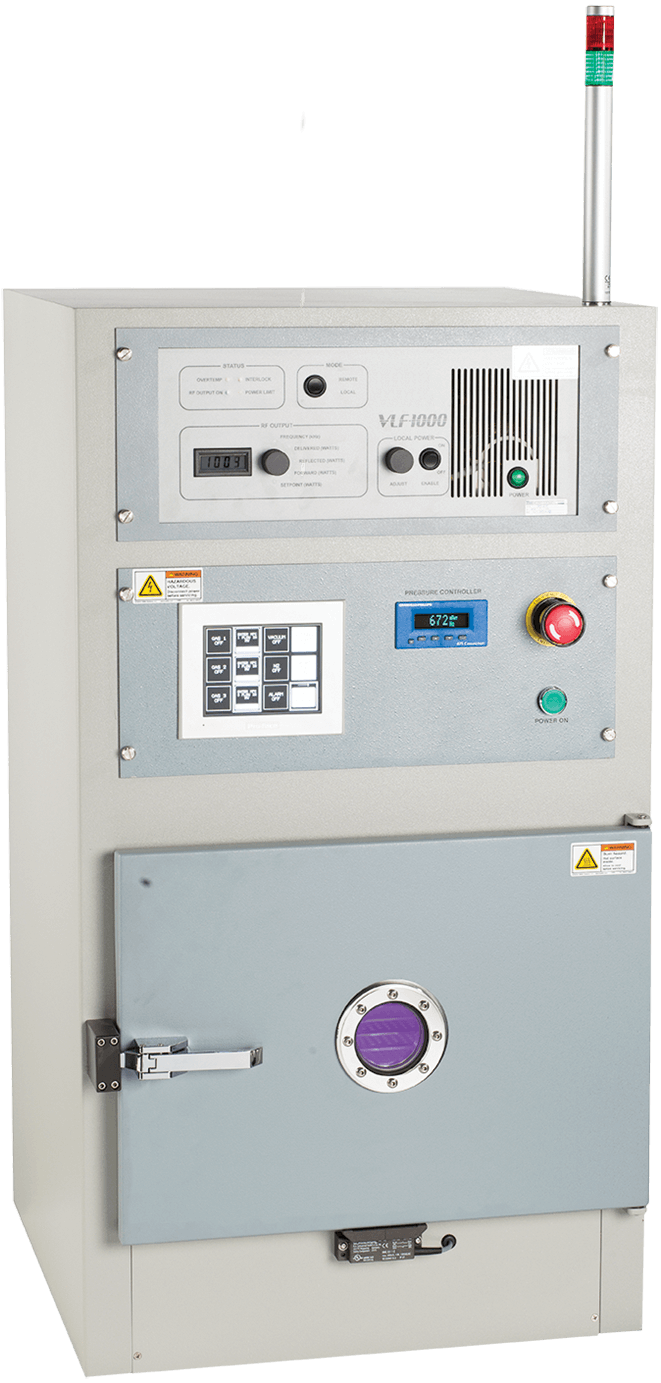

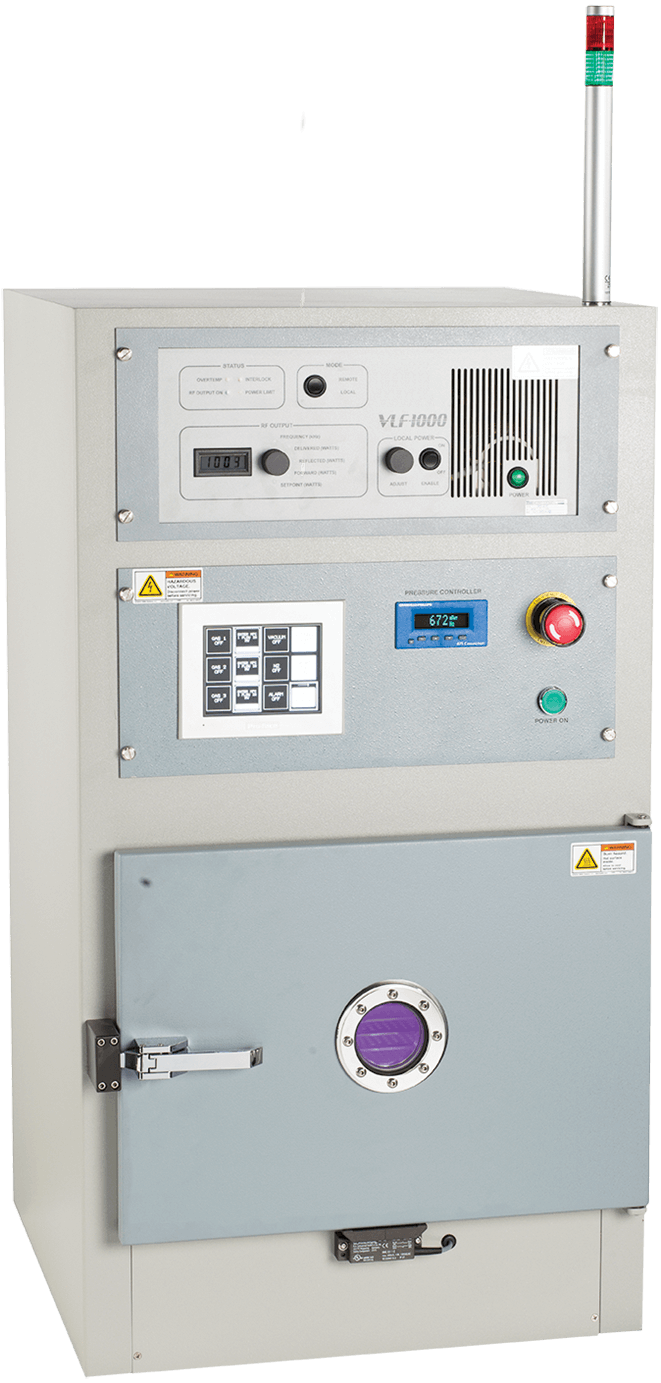

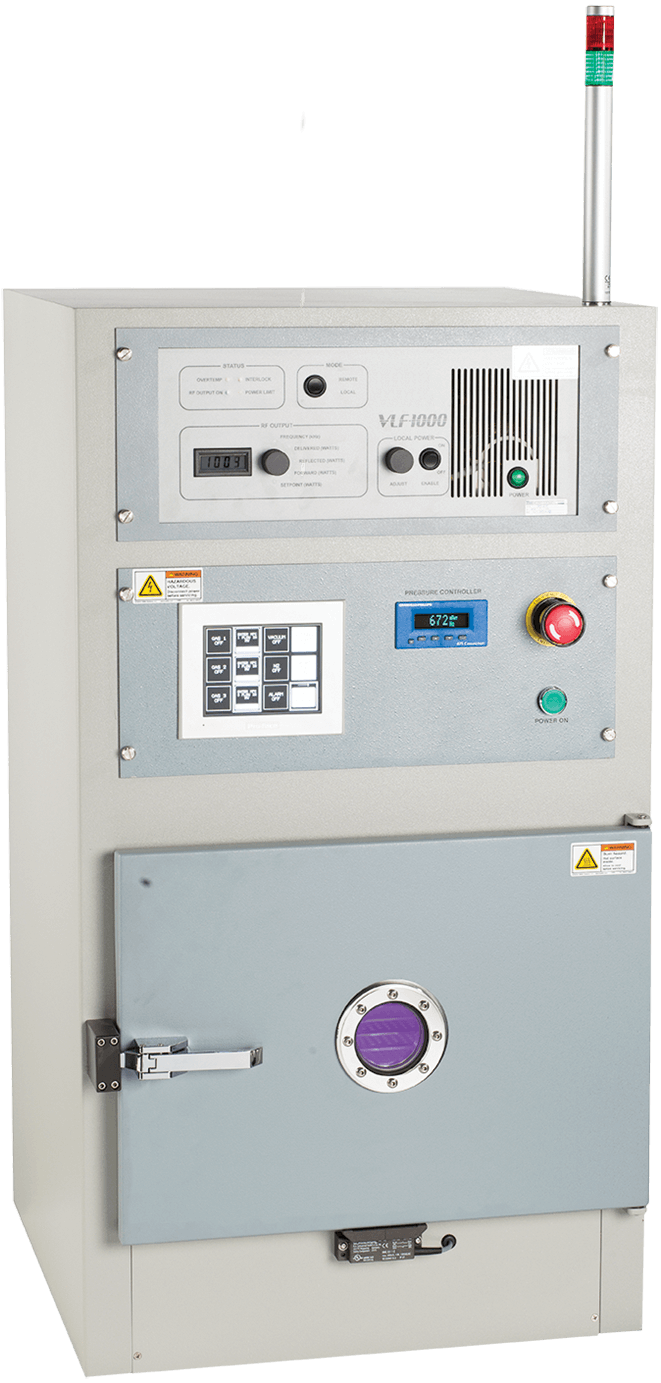

Proven subsystems and YES’s four decades of vacuum technology expertise come together in this low-maintenance, small-footprint system that saves on floor space, chemical consumption, production time, and overall ownership cost.

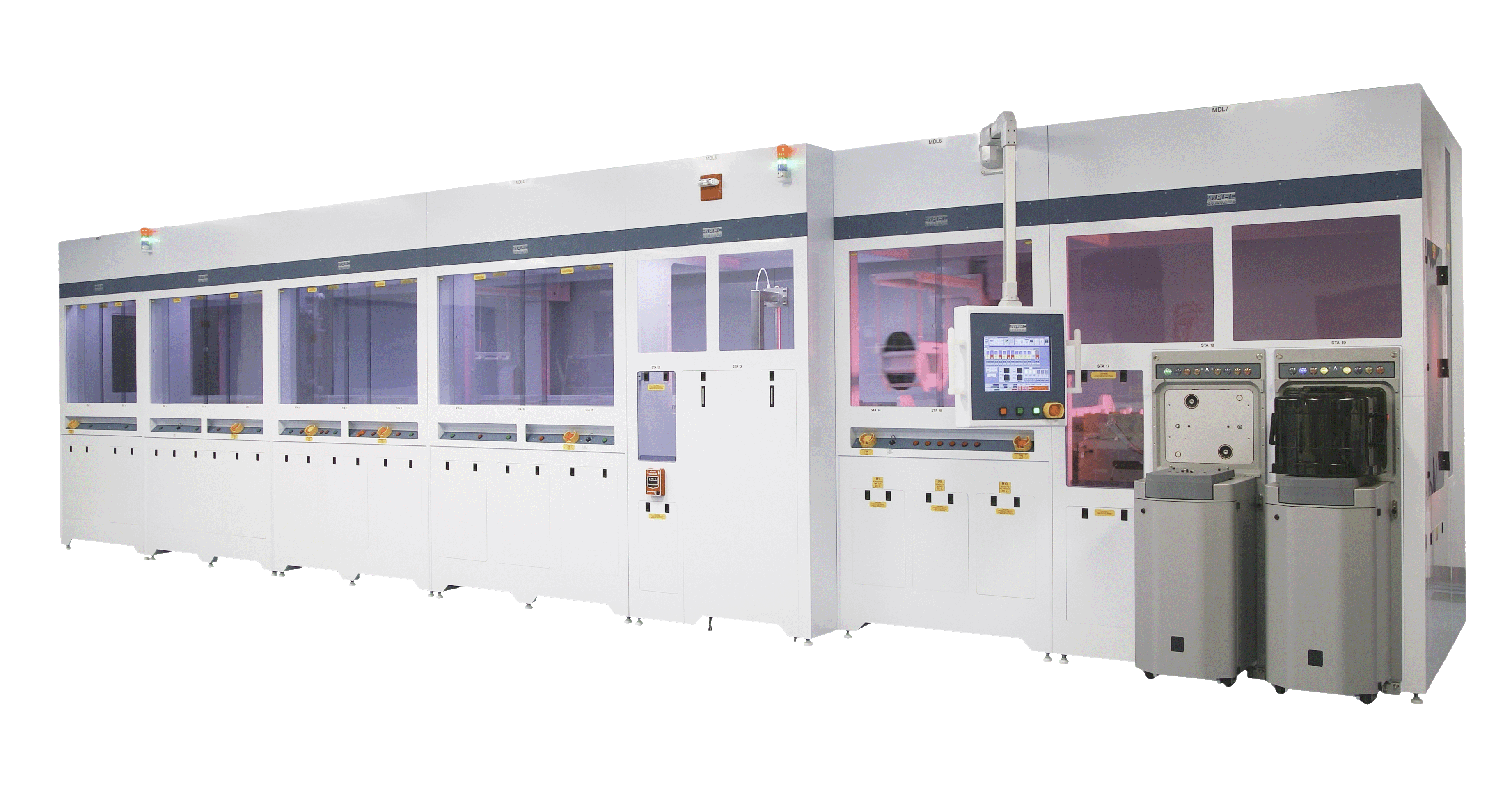

YES offers flexible, configurable automated and manual wet process platforms for a wide range of substrate materials (silicon, glass, SiC, sapphire, GaAs, GaN, Ge, GeN, InP, niobium) and shapes ranging from 150mm, 200mm and 300mm wafers to panels, polysilicon chunks, ingots and medical devices.

Wet processes possible with YES equipment include etch (metal, oxide, nitride, silicon, polysilicon), clean (wafer reclaim, particle removal, poly chunk, critical clean, photomask clean, FEOL, BEOL), strip (photoresist, Ti, nitride), removal (polymer, metal, resist, flux, reclaim, liftoff), extraction (solvents and aqueous), electroless plating (Cu, Ni, Pd, Co, ENEPIG), electrochemical deposition (Cu, Au, Ni, Sn, Co, alloys, Pb-free solder), texturization (damage repair, SAP based metal cleaning, roughening), drying (surface tension gradient, IPA vapor, hot DI slow pull, SRD), chemical delivery (wet bench, fume hood, aqueous, solvent), desmear, and coating.

- Electroless & Electrolytic Plating

- Wet Clean/Etch

- SC1,SC2, Pre-Diffusion Clean

- Metal Etch

- Resist Strip

- Polysilicon Chunk Clean

YES offers a complete portfolio of cassettes and software for YES Clean, Coat, and Cure systems. You may also order customized cassettes and additional replacement parts for YES systems.

Other Parts, Accessories, and Software

Contact us to order replacement door seals and optional parts for your YES equipment.